1.The product is manufactured according to the standard of GB/12706-2002 or IEC,BS,DIN and ICEA upon request.

2 .The product is suitable for use in power transmission and distribution lines with rated power frequency voltage 0.6/1 kV~26/35 kV.

3. Instruction of application

3.1 Rated voltages: 0.6/1 kV~26/35 kV

3.2 The ambient temperature for installation: ≥0°C

3.3 Maximum conductor temperature in normal operation:≤90°C

3.4 Max operating temperature of con. When cable short-circuited (5s maximum duration): 250°C

3.5 Permissible bending radius:

Single cable: [20(D+d) ±5%] mm

Multi cable:[15(D+d) ±5%] mm

Production Range

Model | Nominal Cross Section(mm2) |

Single Core |

NH-VV NH-YJV | 1.5-800 |

NH-VV22 NH-YJV22 | 4-300 |

NH-VV32 NH-YJV32 | 4-300 |

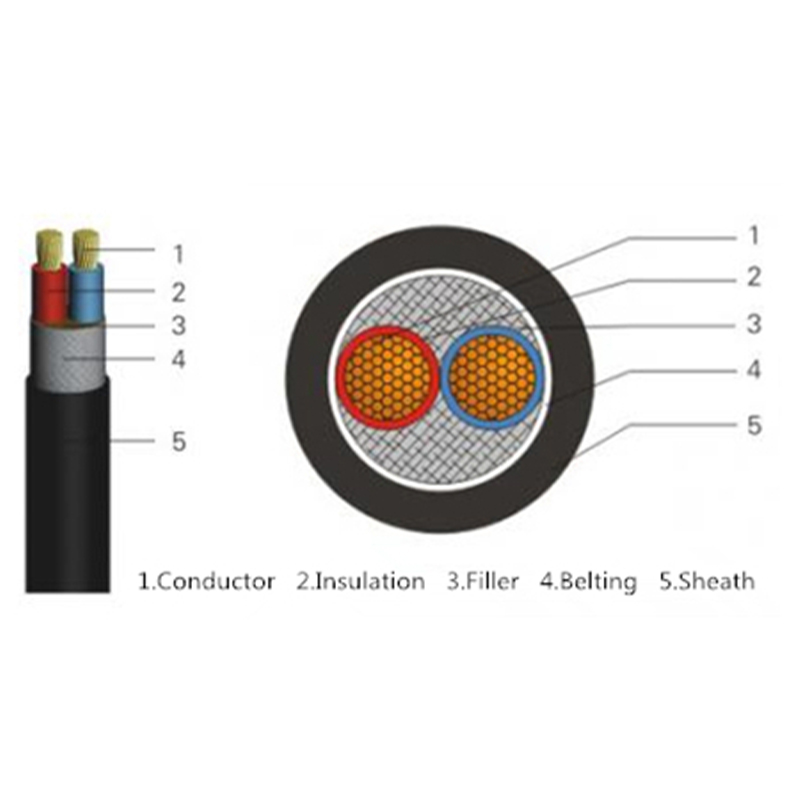

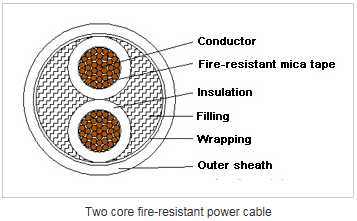

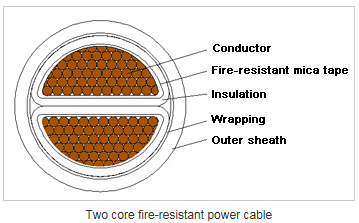

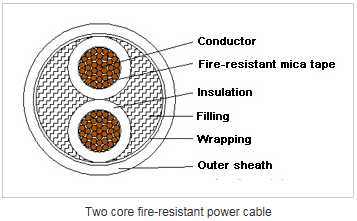

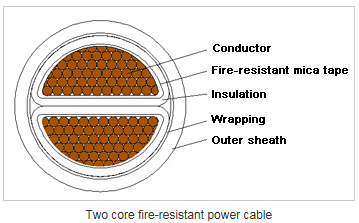

Structure

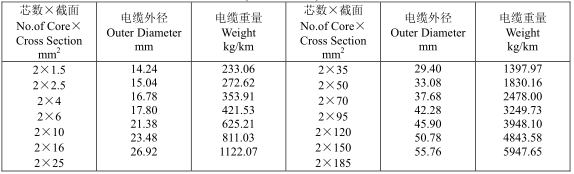

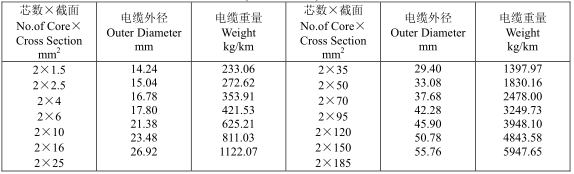

Specification Range,Outside Diameter and Calculated Weight of Unit Length

Table1 0.6/1kV NH-VV fire-resistant cable (double-core)

Packaging : Can as per your requirements.

Power Cable can be packed freely in roll or on wooden/ steel drums.